Better Touch Better Business

Contact Sales at TRANSMART.

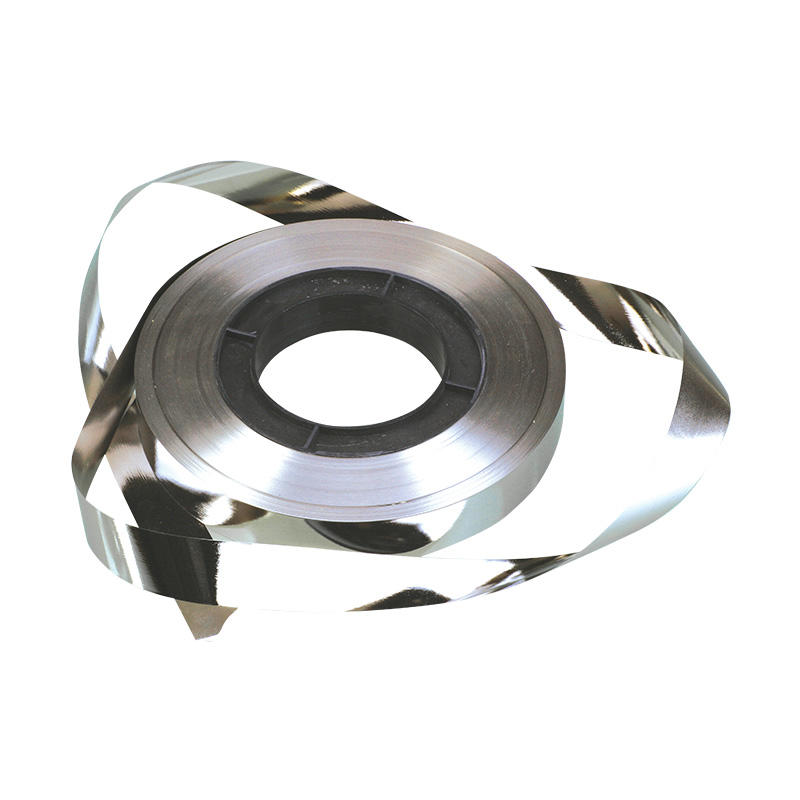

The loss PCM and amplitude permeability µ a of iron-based nanocrystalline alloy core are important performance indicators for the design of high-frequency transformer. After the transformer size is determined, the higher the amplitude permeability µ a, the smaller the transformer input signal; The lower the core loss PCM, the higher the transformer efficiency. If the core loss PCM and amplitude permeability µ a are stable within the service temperature range, the stable operation of high-frequency transformer can be ensured. It can be seen from table 1 and figures 1 and 2 that the permeability of iron core is in the range of - 55 ~ 200 ℃, which increases slightly and changes little with the increase of temperature; The core loss shows a downward trend with the increase of temperature, which does not cause the deterioration of performance. This change should be caused by the influence of temperature on the movement of electrons and magnetic domains. When the temperature continues to rise, the permeability decreases, the core loss increases, and the magnetic properties deteriorate sharply, which no longer has the function of magnetic devices.

It is generally believed that the Curie point is the highest limit of the service temperature of ferromagnetic materials. It can be seen that the Curie temperature of iron-based nanocrystalline alloy is 550 ℃, which is only lower than that of silicon steel, and the alloy core has passed 550 ℃ × After crystallization heat treatment for more than 1h, the microstructure and properties are quite stable. Therefore, within the test temperature range of - 55 ~ 200 ℃, the microstructure and magnetic properties of the iron core cannot change much, so it is in a stable state. If the temperature continues to rise, the effect on the properties of iron-based nanocrystalline alloy core will be inevitable, and the magnetic properties will decline until they disappear. In view of the fact that the heat-resistant temperature of other materials such as enamelled wire for making transformer is generally not more than 150 ℃, the temperature rise during the operation of high-frequency transformer has been fully considered in the product design, so the performance of iron-based nanocrystalline alloy core is stable within the service temperature range. The performance of several common soft magnetic alloys is better than that of alloy µ max / 104 BS / T, iron loss P / w · kg-1 ρ/ µΩ·cm TC/

90 iron based nanocrystalline alloy 30 1.25p0.2/20k = 3.4 ℃

550 Fe based amorphous alloy 15 1.56p1.0/1k = 4 140 415 Co based amorphous alloy 80 0.57p0.5/10k = 4 140 340 permalloy 1j8518 0.70 p0.5/10k = 45 56 400 power ferrite 0.5 0.5 p0.2/20k = 7.5 5 5 × 107 220 cold rolled silicon steel 4 2.03 P1.0 / 1K = 20 47

740. There is no problem in meeting the use requirements. Feng Yi and others have studied the changes of p0.4/10k, p0.5/20k, p0.3/50k and p0.2/100k iron losses of iron-based nanocrystalline alloy core for electronic transformer in the temperature range of - 55 ~ 180 ℃. The results show that the iron loss PCM under different frequencies and magnetic induction intensity changes little, the performance fluctuation range is within the requirements of magnetic devices, and meets the technical performance requirements of military electronic products (± 8%), which is consistent with our research results. 4.2 iron based nanocrystalline magnetic particle core magnetic particle core products are mainly used as inductive devices. The inductance L is directly proportional to the effective permeability µ e of the magnetic particle core, and the quality factor Q is the performance of the loss of the magnetic particle core. It can be seen that the inductance L of four samples with different effective permeability µ e changes little in the temperature range of - 55 ~ 150 ℃; The quality factor Q value increases at low temperature, and there is little change at - 20 ~ 150 ℃. The reason for stable performance is the same as the above analysis. The lower the loss of magnetic particle core in low temperature section, the higher the quality factor Q value.

Conclusion various iron core devices made of iron-based nanocrystalline alloy prepared by rapid quenching technology have passed 550 ℃ × After partial crystallization heat treatment for more than 1h, the microstructure and properties are quite stable. By testing the magnetic properties of several common iron-based nanocrystalline alloy core devices in the temperature range of - 55 ~ 150 ℃, it shows that the iron-based nanocrystalline alloy core products do have good temperature stability, which provides a basis for users to use with confidence.

Copyright © 2025 TRANSMART INDUSTRIAL LIMITED | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.