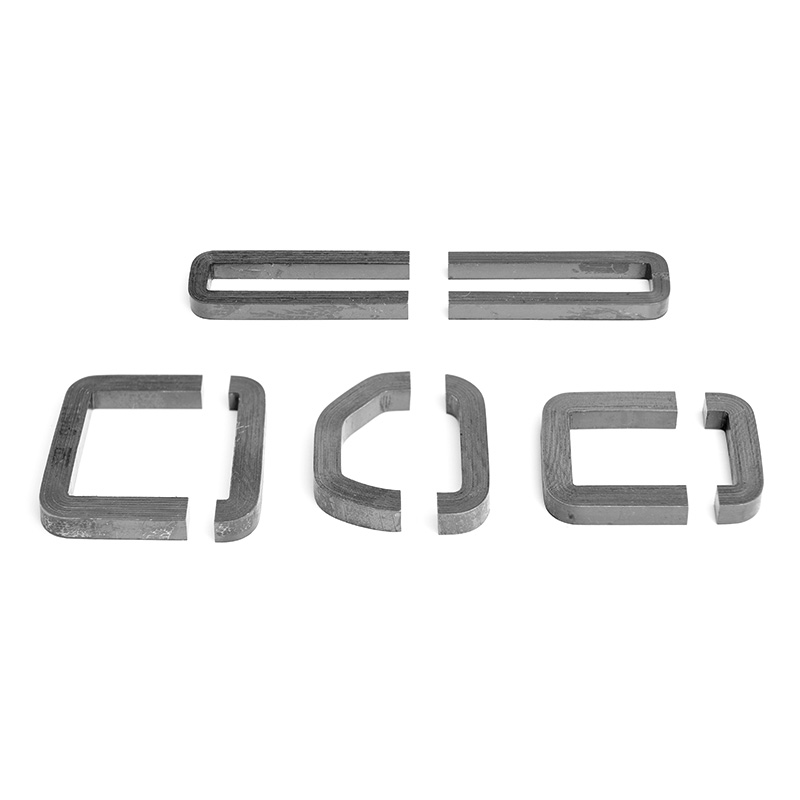

Related Products

| Brand: | Transmart |

|---|---|

| Model: | Baosteel, JFE |

| MOQ: | 100 PCS per item |

| Origin: | China Foshan |

| Lead time: | 4-15 Working days |

| Payment: | L/C D/A D/P T/T Western Union |

| Service: | OEM, ODM, Customized |

Copyright © 2025 TRANSMART INDUSTRIAL LIMITED | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.