Better Touch Better Business

Contact Sales at TRANSMART.

Amorphous nanocrystalline soft magnetic materials are known as the new green energy-saving materials in the 21st century because of their excellent properties such as high permeability, high saturation magnetic induction, low loss, and good thermal stability. In addition, their process is simple and cost-effective. Low cost, and now it has been widely used in communications, industry, new energy, power electronics and other industries. Looking at the world, domestic amorphous and nanocrystalline soft magnetic material companies have become the main force in the production of amorphous and nanocrystalline products.

At present, the domestic amorphous nanocrystalline strip technology is relatively mature, and mass production of ultra-thin strips can be realized by the melt state quenching method to meet the application needs of the soft magnetic field. It is reported that more and more domestic enterprises choose amorphous and nanocrystalline materials as their main products to promote the high frequency, miniaturization, environmental protection and energy saving of electronic products, which has played an important role in the development of my country's electronic manufacturing industry.

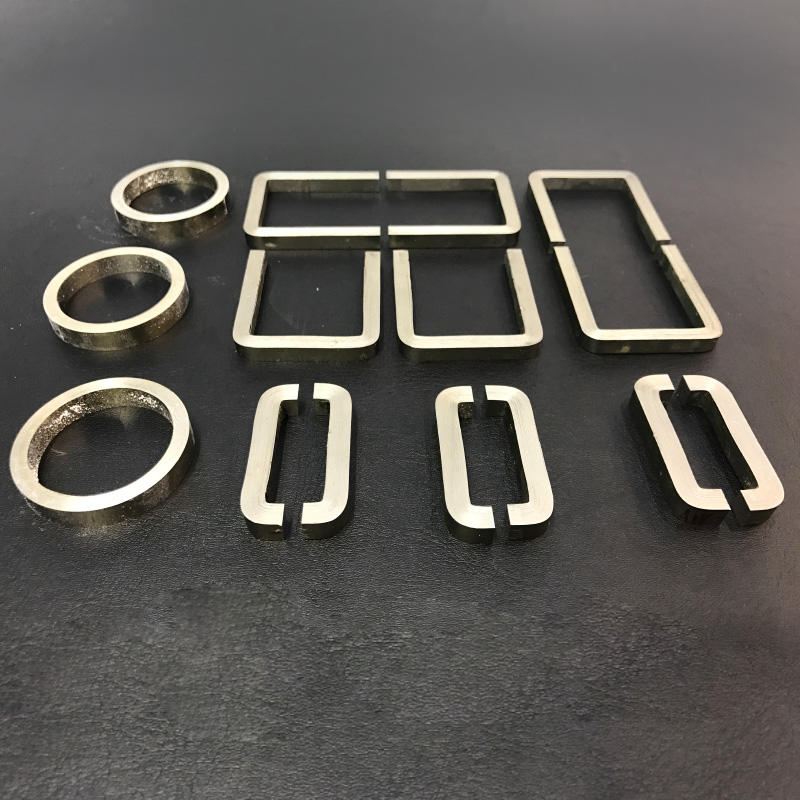

Transmart is committed to the research and development, production and sales of amorphous, nanocrystalline and permalloy magnetic core products. Its main products are: nanocrystalline ribbons, ultra-microcrystalline iron cores, ultra-microcrystalline magnetic cores, permalloy magnetic cores, Products such as high-power transformer cores, nanocrystalline magnetic loop inductors, electromagnetic loop coils, open-close transformers, common-mode inductance coils, and precision current transformers have the advantages of good stability and high electrical parameters.

The company has multiple vacuum heat treatment furnaces, hydrogen annealing furnaces, automatic magnetic core winding machines, automatic magnetic material detection systems, multiple automatic winding machines, and various equipment and precision testing instruments. The annual output of nanocrystalline and permalloy magnetic cores reaches more than 80 million. We can customize and develop microcrystalline, nanocrystalline magnetic cores, permalloy core related products and various magnetic toroidal inductors for customers.

Copyright © 2025 TRANSMART INDUSTRIAL LIMITED | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.