Better Touch Better Business

Contact Sales at TRANSMART.

The transformer core is an important component in high-power inverter power supplies, which requires relatively high magnetic permeability, good thermal stability, and especially low losses. Because this type of transformer is a power transmission component, when the frequency is high, each kilogram of magnetic core needs to transmit 10-15 kilowatts of energy. The energy density per unit volume or weight is very high, which requires that the iron loss of the transformer core must be very small.

The transformer core is an important component in high-power inverter power supplies, which requires relatively high magnetic permeability, good thermal stability, and especially low losses. Because this type of transformer is a power transmission component, when the frequency is high, each kilogram of magnetic core needs to transmit 10-15 kilowatts of energy. The energy density per unit volume or weight is very high, which requires that the iron loss of the transformer core must be very small.

In recent years, the application of amorphous and nanocrystalline alloys in high-power inverter power sources has continued to grow. Due to the need for energy conservation and the continuous improvement of environmental requirements, the market urgently needs to provide high-power inverter power cores with better performance and lower losses. At present, the materials used for the magnetic cores of high-power inverter power supplies above KVA level are mainly amorphous and nanocrystalline soft magnetic alloys, with only a small number of smaller power supplies using power ferrite.

Nanocrystalline materials have a combination advantages of silicon steel, permalloy and ferrite, the working frequency of high frequency inverter power supply is 20 kHz ~ 50 kHz, as the heart of main power supply transformer, although the traditional ferrite core material loss at high frequency is low, but the permeability of below 100 kHz frequency is relatively low, and its saturation magnetic flux density value (Bs) is also low, the volume and weight of the iron core is still large. In addition, because of low Curie temperature, weak thermal stability, Bs value decreases quickly when little temperature rise, easy to saturation and working condition is not stable, ferrite is not suitable for high frequency power. Nanocrystalline materials have excellent comprehensive magnetic properties, especially applicable in high-power and high-frequency inverter power core.

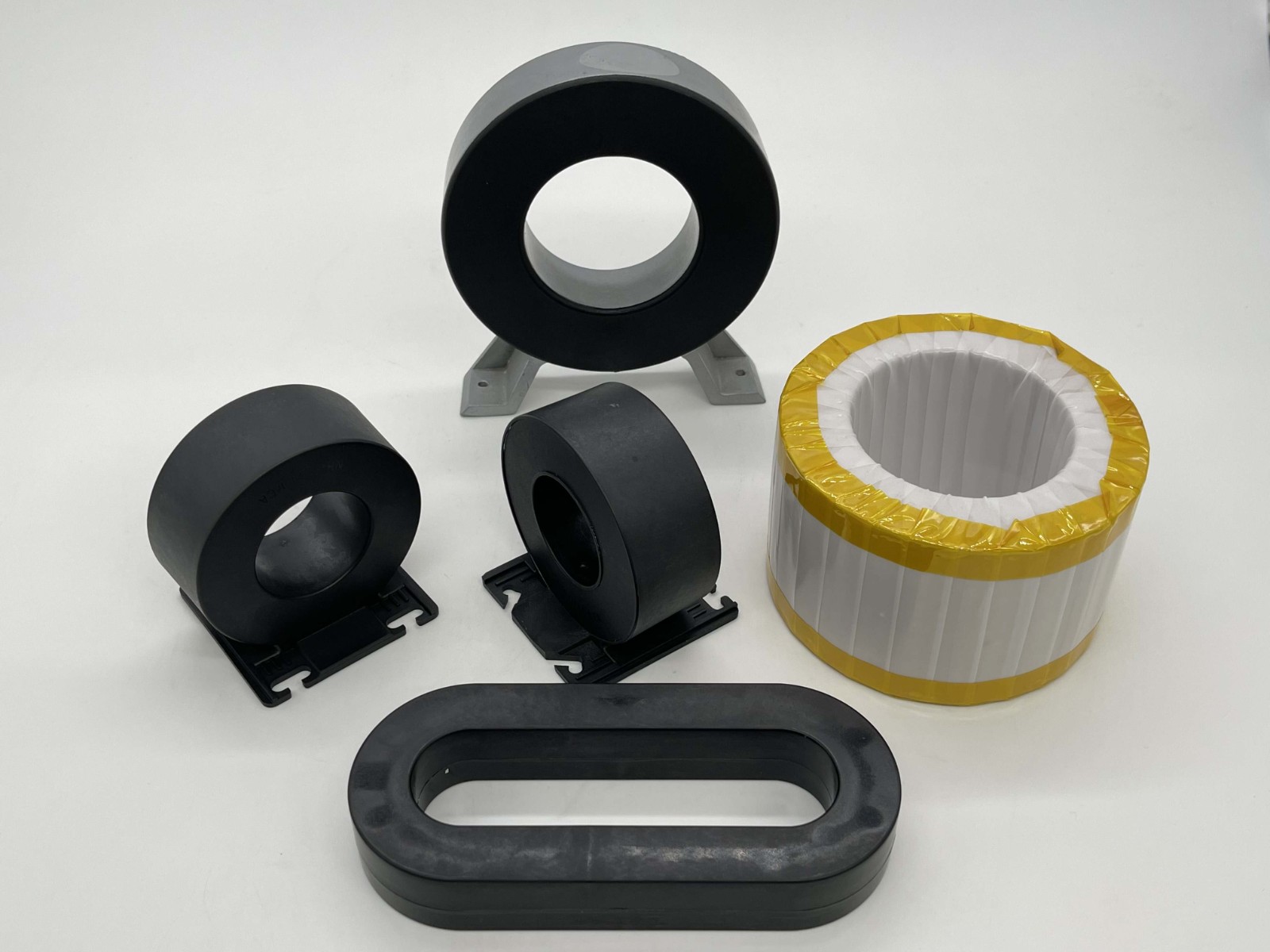

Transformers are mainly composed of magnetic cores and coils. For high-power inverter power transformers, due to their high frequency, the number of coil turns is not large, but the current is relatively large, so the wires are relatively thick. Considering the skin effect of the coil, multiple strands of thin wire are used. The winding and weight of the coil will form a significant stress on the magnetic core. Therefore, a suitable skeleton or protective box becomes another key to high-power inverter power transformers.

Unlike ferrite magnetic cores, the shape of nanocrystalline alloy thin strip magnetic cores in their free state is prone to deformation. When such deformation occurs, the magnetic properties deteriorate sharply. Therefore, it is necessary to skeleton or install protective boxes on the surface of nanocrystalline alloy soft magnetic cores for protection. Installing the magnetic core into a closed protective box or using surface spraying or electrostatic spraying to form a resin or plastic protective layer is a conventional protection method. Another solution is to wrap the outer surface of the magnetic core with glass fiber and add an epoxy resin layer.

Unlike ferrite magnetic cores, the shape of nanocrystalline alloy thin strip magnetic cores in their free state is prone to deformation. When such deformation occurs, the magnetic properties deteriorate sharply. Therefore, it is necessary to skeleton or install protective boxes on the surface of nanocrystalline alloy soft magnetic cores for protection. Installing the magnetic core into a closed protective box or using surface spraying or electrostatic spraying to form a resin or plastic protective layer is a conventional protection method. Another solution is to wrap the outer surface of the magnetic core with glass fiber and add an epoxy resin layer.

Due to the common feature of the above protection methods being sealed magnetic cores, they have the advantages of high strength, low stress, and compact structure. However, the heat generated by the loss during the operation of the iron core is not easily dissipated, and the coil winding outside the magnetic core also heats up, ultimately causing the temperature inside the magnetic core to become higher and higher, causing the transformer to burn out or fail to work due to excessive temperature rise. This issue is a prominent contradiction for high energy density power components such as the main transformer of the inverter power supply. If the magnetic core does not generate heat without loss or has extremely low loss, the above problem does not exist. It can be seen that reducing the loss of magnetic cores is a crucial solution for power magnetic cores.

During the entire process of using nanocrystalline magnetic rings (ultra microcrystalline iron cores) in inverter power supplies, there have been some problems such as noise, ductility, consistency, etc. These problems have already been gradually addressed. High power inverters and switching power supplies have developed relatively mature and are widely used in various fields. They have the advantages of small size, high efficiency, energy conservation and environmental protection. At present, it has been widely used in industries such as inverter welding machines, power systems, electroplating process electrolysis power supplies, induction heating equipment, charging power supplies, etc., and there will be even greater improvements in the next two years.

Copyright © 2025 TRANSMART INDUSTRIAL LIMITED | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.