Better Touch Better Business

Contact Sales at TRANSMART.

Power efficiency is frequently known as the output power to input power ratio. It is a vital component in several electrical devices and systems. How well electrical energy can be transformed and used is greatly influenced by these materials. In this blog post we will talk about the world of soft magnetic core materials in this post and examine how they are revolutionizing power efficiency in a variety of applications.

The Function of Magnetic Core Materials

Let's first comprehend the essential function of core materials in electrical devices in order to grasp their influence on power efficiency.

Transformers, inductors, and chokes all have core materials as an essential component. They perform a number of crucial tasks:

1. Magnetic Path: Cores give the magnetic flux that is produced by the electrical current flowing through the coil windings a low-resistance route. As a result, energy is transferred effectively.

2. Magnetic Field Control: Cores help focus and direct the magnetic field within the core material, guiding it to interact with the coil windings in an efficient manner.

3. Control of Inductance: The kind of core material and its characteristics affect the coil's inductance, which affects the device's impedance, reaction time, and energy storage capability.

4. Reduction of Eddy Current Losses: Eddy currents, induced currents that move around inside the core material, can result in energy losses by producing heat. These losses are reduced by selecting the right core material.

Standard Magnetic Core Materials

Electrical devices have historically made use of a number of fundamental materials, each with advantages and disadvantages:

1. Iron and Steel: Conventional iron and steel cores have a high magnetic permeability, which makes them perfect for uses requiring high magnetic flux densities. Hysteresis and eddy current effects, though, can cause them to experience core losses.

2. Ferrite: Due to their high electrical resistivity and low eddy current losses, ferrite cores manufactured of ferrite ceramic materials are appropriate for high-frequency applications. Compared to iron and steel, they typically have a lesser permeability.

Transformer Magnetic Core Materials

Transformer core materials have surfaced in recent years, bringing fresh approaches to the problem of increasing power effectiveness. These materials have provided new opportunities for a variety of sectors looking to maximize energy efficiency and cut costs. The following are a few of the transformer core materials having a big impact:

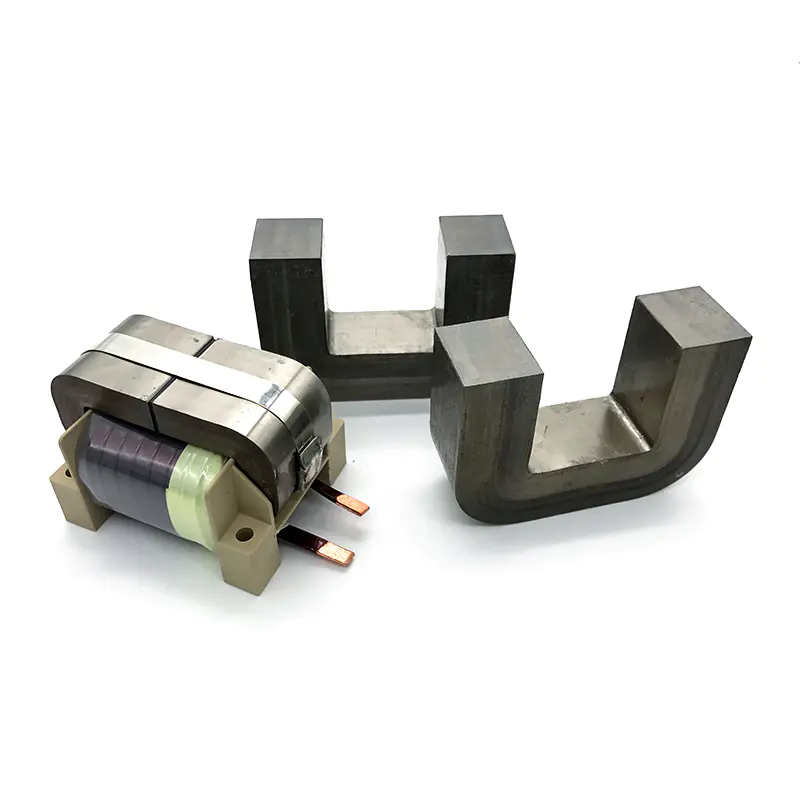

The most innovative magnetic cores today are nanocrystalline. These cores are made of nanocrystalline alloys with incredibly small grains, frequently on the nanometer scale, that are primarily silicon and iron-based.

Nanocrystalline cores are incredibly efficient because they have reduced core losses. They are perfect for uses like high-efficiency transformers and inductors where reducing energy loss is important.

Materials with disordered atomic structures are used to create amorphous magnetic cores, commonly referred to as metallic glass cores. These cores have outstanding soft magnetic characteristics, such as minimal core loss and coercivity.

Power electronics depend heavily on amorphous cores, particularly in high-frequency transformers and inductors. In applications where energy efficiency is crucial, their special magnetic properties help to reduce energy losses and improve the effectiveness of electrical devices. This makes them an invaluable tool.

3.Powder Cores

Powder cores are composite materials made of non-magnetic binder and magnetic powder particles. The magnetic properties of conventional ferrite and iron cores are harmoniously balanced by this design.

High magnetic permeability, reduced core loss, and exceptional thermal stability are all features of powder cores. In high-frequency applications like power converters, where the capacity to withstand high-flux densities and retain low losses is essential, these qualities are very helpful.

4. Soft Ferrite Cores

Research and development on soft ferrite cores have continued, resulting in the development of better materials with greater characteristics. Soft ferrites have good noise-suppression abilities, high permeability, and low core loss.

Inductors, noise filters, and radio frequency (RF) transformers all make substantial use of these cores in wireless communication systems. Modern electronic equipment benefit greatly from their capacity to suppress electromagnetic interference (EMI), which maintains signal integrity and limits interference.

5.Composite Cores

Composite magnetic cores combine various materials to take advantage of each component's strengths. By combining low core loss, high permeability, and great frequency responsiveness, a composite core, for instance, might contain both nanocrystalline and amorphous materials.

Composite cores are flexible and have a variety of uses, such as electromagnetic interference filters, power supply, and renewable energy systems, demonstrating their flexibility to many industries.

Transformer Core Material Applications

A new era of electrical device performance and efficiency has begun as a result of advances in core materials. These materials are used in a variety of contexts and industries:

1. Power Electronics: The low core losses of nanocrystalline and amorphous cores are very advantageous for high-efficiency power converters, inverters, and energy storage systems. These substances play a crucial role in minimizing energy waste and raising power conversion efficiency.

2. Renewable Energy: To enhance energy conversion and grid integration, wind turbines and solar inverters rely on small, effective power electronics. Low loss magnetic cores are essential to the overall effectiveness of renewable energy systems.

3. Electric Vehicles (EVs): In the EV industry, where efficiency and space are crucial, magnetic cores with low losses support effective motor drives and charging systems, extending battery life and EV range.

4. RF and Communication Devices: RF transformers, inductors, and filters used in wireless communication systems require soft ferrite and composite cores. For dependable communication, their cores provide signal integrity and EMI suppression.

5. Industrial Automation: To preserve operational effectiveness and dependability, high-frequency power supplies, motor drives, and automation systems in industrial environments benefit from enhanced magnetic cores.

The Prospects for Power Efficiency

The advancement of power efficiency will depend heavily on developments in core materials as the demand for energy-efficient solutions keeps rising. To further improve the capabilities of magnetic cores, scientists and engineers will probably keep looking at novel materials and design strategies.

These developments are making the path for a future. This will be technologically advanced and redefining how we harness electrical energy.

Transmart transformer core manufacturers offers high-quality transformer cores including nanocrystalline core, amorphous core, silicon steel core and common mode chokes.

Copyright © 2025 TRANSMART INDUSTRIAL LIMITED | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.