Better Touch Better Business

Contact Sales at TRANSMART.

The iron core is the main part of the magnetic circuit in the transformer. It is usually made of hot-rolled or cold-rolled silicon steel sheets with high silicon content and coated with insulating paint. The iron core and the coil wound on it form a complete electromagnetic induction system. The transmission power of power transformer depends on the material and cross-sectional area of iron core.

Classification introduction

1. High frequency: iron powder core ferritecore

Ferritecore is used in high-frequency transformer. It is a ceramic magnet with spinel crystalline structure. This spinel is iron oxide and other divalent metal compounds, such as kfe2o4 (k represents other metals). At present, the commonly used metals are manganese (MN), zinc (Zn), nickel (Ni), magnesium (NG) and copper (Cu)

Its common combinations are manganese zinc (MnZn) series, nickel zinc (NiZn) series and magnesium zinc (MgZn) series. This material has the physical properties of high permeability and impedance, and its service frequency range is from 1kHz to more than 200kHz

2. Low frequency: silicon steel sheet

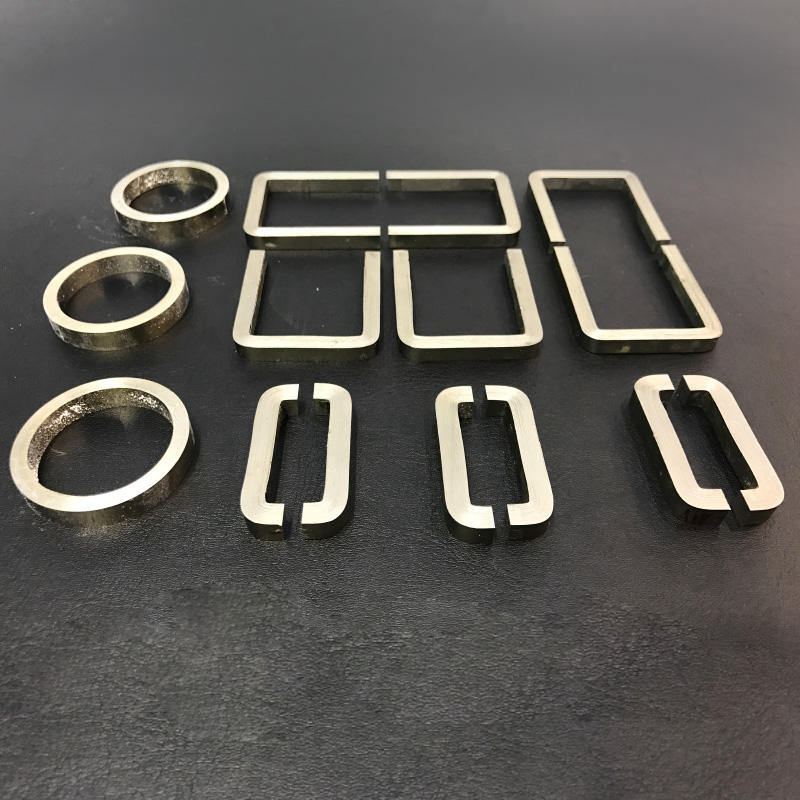

Silicon steel sheet is used in low-frequency transformer. There are many kinds. According to its manufacturing process, it can be divided into a: Calcined (black sheet) and N: non calcined (white sheet). According to its shape, it can be divided into EI type, UI type, C type and mouth type.

Mouth silicon steel sheet is often used in transformers with high power. It has good insulation performance, easy heat dissipation and short magnetic circuit. It is mainly used in transformers with power greater than 500 ~ 1000W and high power. A set of silicon steel sheets composed of two C-type silicon steel sheets is called CD type silicon steel sheet. The window of the power transformer made of CD type silicon steel sheet is higher and higher under the condition of the same cross-sectional area.

The greater the power of the transformer, coils can be installed on both sides of the iron core, so the number of coil turns of the transformer can be distributed on two wire packages, so that the average turn length of each wire package is shorter and the copper consumption of the coil is reduced. In addition, if two coils requiring symmetry are wound on two wire packages respectively, the effect of complete symmetry can be achieved. A set of silicon steel sheets composed of four C-type silicon steel sheets is called ed type silicon steel sheet. The transformer made of ED type silicon steel sheet has a flat and wide shape. Under the condition of the same power, the ED type transformer is shorter and wider than the CD type transformer. In addition, because the coil is installed in the middle of the silicon steel sheet and has an external magnetic circuit, the magnetic leakage is small and the overall interference is small. However, all its coils are wound on a wire package, The wire package is thick, so the average turn length is long and the copper consumption is large.

The C-type iron core has excellent performance. The transformer made of it has the advantages of small volume, light weight and high efficiency. From the perspective of assembly, there are few parts of C-type silicon steel sheet and strong universality, so the production efficiency is high. However, there are many processing procedures of C-type silicon steel sheet, the work is more complex, and it needs to be manufactured with special equipment, so the cost is still high at present.

E-type silicon steel sheet is also called shell type or Japanese type silicon steel sheet. Its main advantage is that the primary and secondary coils share a wire frame and have a high window duty factor (duty factor km: Net cross-sectional area of copper wire and window area ratio); The silicon steel sheet forms a protective shell for the winding, so that the winding is not vulnerable to mechanical damage; At the same time, the heat dissipation area of silicon steel sheet is large and the magnetic field divergence of transformer is less. However, its primary leakage inductance is large and the interference of external magnetic field is large. In addition, due to the long average circumference of winding, under the condition of the same number of turns and cross-sectional area of iron core, the transformer with EI iron core uses more copper wires.

The thickness of silicon steel sheet is usually 0.35mm and 0.5mm.

There are two assembly methods of silicon steel sheet: overlapping method and opposite stacking method. The overlapping method is to alternately distribute the openings of silicon steel sheet one-to-one on both sides. This stacking method is more troublesome, but the gap of silicon steel sheet is small and the magnetic resistance is small, which is conducive to increasing the magnetic flux. Therefore, this method is used in power transformers. The opposite stacking method is often used in occasions with DC current. In order to avoid saturation caused by DC current, There needs to be a gap between silicon steel sheets. Therefore, for the stacking method, place sheet E and sheet I respectively, and the gap between them can be adjusted by paper.

3. Coil class: divided into three types

A. Toroid ring iron core: it is formed by laminating O-shaped sheets or winding silicon steel sheets. This kind of iron core is very difficult for winding.

B. Rodcore rod core.

C. Drumcore: drum core.

Copyright © 2025 TRANSMART INDUSTRIAL LIMITED | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.