Better Touch Better Business

Contact Sales at TRANSMART.

You've probably heard of Transformers. No, not the robots that turn into cars, but the electrical devices that are crucial in power systems. The transformer core material plays a vital role in how efficiently the CT operates and measures current. In this blog post, we will delve into the world of current transformer cores, exploring different types and their advantages. Let's get started.

Iron cores are the traditional choice for many applications. They offer high magnetic permeability and low core losses, making them efficient for general-purpose use. But they're not perfect. Iron cores can be susceptible to saturation, a state where the core can't handle any more magnetic flux, leading to inaccuracies.

So when should you opt for an iron core? They're ideal for applications where you need a balance of efficiency and cost-effectiveness. They're the "jack-of-all-trades" in the world of current transformer cores. But if you're dealing with specialized needs, you might want to look elsewhere.

Ferrite cores are the modern marvels of the current transformer world. Made from ferrimagnetic ceramic compounds, these cores offer high-frequency operation with low core losses. They're lighter and more compact than their iron counterparts, making them ideal for portable or space-constrained applications.

But where do ferrite cores really shine? In high-frequency applications. If you're dealing with radio frequencies or fast-switching digital circuits, ferrite is the way to go. However, they can be more expensive and less suitable for low-frequency, high-power applications. So, weigh your needs carefully.

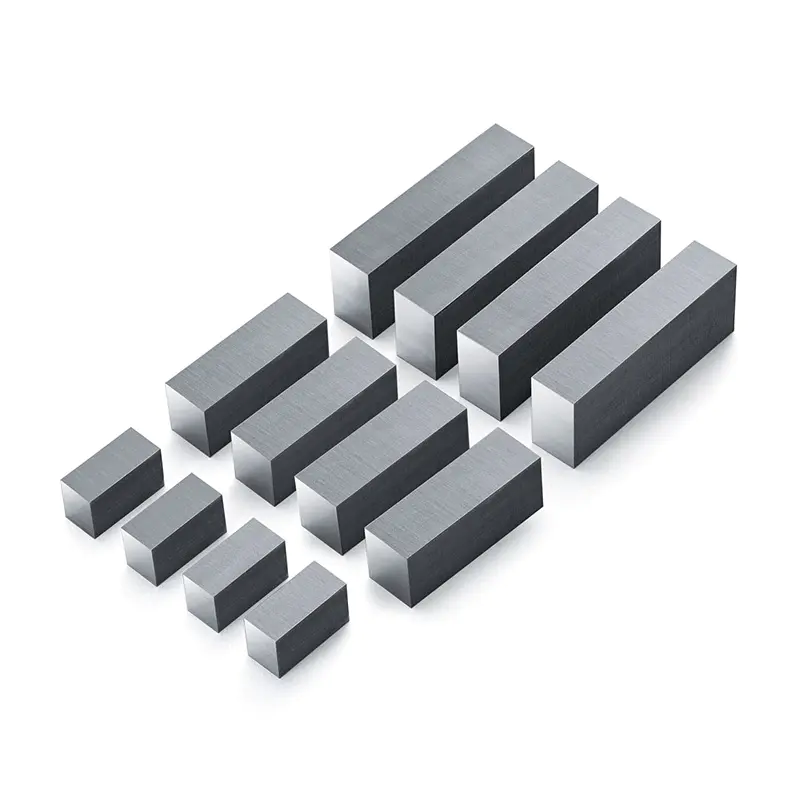

Silicon steel cores are another popular choice for current transformer cores due to their high magnetic permeability and low core losses. These cores are made from a material called electrical silicon steel, which is an alloy of iron and silico.

One key advantage of silicon steel cores is their ability to handle higher levels of primary current without saturating. This means they can accurately measure high currents without distortion or loss of accuracy.

Additionally, silicon steel cores have excellent temperature stability, making them ideal for applications in harsh environments where temperatures may vary widely. They also exhibit low hysteresis losses, ensuring efficient energy transfer and minimal heat generation.

Let's get a bit technical, but not too much. The core works on the principle of electromagnetic induction. When alternating current flows through the primary winding, it creates a magnetic field. This magnetic field induces a voltage in the secondary winding, which is then used for measurement or control. Simple, right?

The core material determines how efficiently this magnetic coupling happens. Different materials have different magnetic permeabilities, which is a fancy way of saying they conduct magnetic fields differently. The better the material, the more accurate your current measurements will be. So, choosing the right core is not just a matter of preference; it's a matter of precision.

The core isn't just a hunk of metal or air; it's the linchpin of your current transformer. It determines how efficiently and accurately the transformer operates. A poor-quality core can lead to inaccurate measurements, reduced efficiency, and even safety risks.

Why is the core so crucial? It affects everything from the transformer's sensitivity to its power handling capabilities. A well-chosen core can make your transformer more versatile, more reliable, and safer to use. So, when you're selecting a transformer core, think of it as an investment in quality and performance.

Choosing the right core is like picking the right engine for your car—it's a decision that impacts performance, efficiency, and reliability. You can't afford to wing it.

Accuracy - Accuracy is one of the most crucial factors to consider when selecting a current transformer core. The accuracy of the core directly impacts the precision of the measurements it provides. Depending on your specific application requirements, you may need a core with higher or lower accuracy levels.

Size and weight - Size and weight are practical considerations when choosing a current transformer core. The size and weight of the core can affect its installation and overall functionality in your system. If space is limited or if portability is important, you may opt for a smaller and lighter core.

Cost - Cost is another significant factor that cannot be overlooked. Different types of cores come at different price points, so it's essential to consider your budget constraints along with other performance requirements. It's worth noting that while some cores may be more expensive upfront, they might offer better long-term value due to their durability and accuracy.

Other factors such as frequency response, linearity, temperature range, and voltage rating should also be taken into account depending on your specific application needs.

By carefully considering these factors along with any unique requirements for your project, you can make an informed decision about which type of current transformer core will best suit your needs.

Choosing the right current transformer core for your current transformer is crucial to ensuring accurate and efficient measurement of electrical currents. Different types of cores offer unique characteristics and advantages, allowing you to select the best option for your specific application.

When selecting a current transformer core, consider factors such as the required accuracy level, size constraints, frequency range, and cost considerations. It's essential to consult with experts or refer to manufacturer specifications to ensure compatibility with your specific needs.

In conclusion, understanding the different types of current transformer cores empowers you to make an informed decision that optimizes performance while meeting your operational requirements seamlessly.

Ready to take the next step in selecting the perfect core for your current transformer? Head over to our extensive product range at Transmart to find the core that's just right for you. Don't settle for less; choose quality, performance, and reliability with Transmart.

Copyright © 2025 TRANSMART INDUSTRIAL LIMITED | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.