Better Touch Better Business

Contact Sales at TRANSMART.

A toroidal transformer is a type of power transformer formed by a donut-shaped magnetic core. The toroidal transformer coreis made from ferromagnetic materials such as silicon steels, laminated iron, ferrite rings, etc. The primary and secondary coils wound around these transformer cores alter the alternating current to produce the required output voltage.

Factors such as the kind of wire, number of winding turns, the wire's cross-section, and the wire's current-carrying capacity are considered while making the transformer core.

The toroidal transformer alters the alternating current (AC) by converting it from one level to another. The current flows from the primary coil to generate the magnetic field. This magnetic field produces an electric current in the secondary coil to generate the required output voltage.

The coils are tightly wound around the symmetrical core, allowing only a small amount of magnetic flux (10% to 20% of the total transformer losses) to escape. The shape of these transformer cores can be rectangular, square, or circular.

The alternating current moves in a sine wave pattern. The AC voltage begins at zero volts and reaches its highest positive peak to create a positive magnetic field in the primary coil before falling to 0 amperes again. This completes the first half of the cycle.

The current then rises again to climb to its peak in the opposite direction and creates a negative magnetic field before falling back to 0 volts again.

These rising and falling magnetic fields pass through the secondary coil wrapped around the transformer coreto generate the output voltage.

Several factors, such as the type of wire, number of winding turns, cross-section, and current-carrying capacity of the wire, should be kept in mind while building a toroidal transformer core.

To build a soft magnetic cores, you need to select the material of the magnet wire. Aluminum and copper wires are used for winding these transformer cores. Generally, copper is preferred by transformer core manufacturers for toroidal transformers because of its current carrying capacity, thermal properties, and cost.

The number of winding turns and how evenly the wires are wound around the toroidal transformer cores are important to ensure a minimal stray loss. Transmart Transformer core manufacturers use techniques such as the back-winding technique or interwinding insulation technique to turn wire around the core.

The cross-section of the wire determines the output current and, ultimately, the power of the toroidal transformer. Also, it is important to consider the appliance's watts while determining the wire's current capacity.

Consider you are making a toroidal transformer for an amplifier measuring 800 watts. If your input voltage is 110, divide the watts by the voltage to find out the required current or amps of the wire.

Toroidal transformer cores are better than other transformer cores, such as EI cores, primarily because of their shape and are shaped as a donut to ensure the Electromagnetic Interference (EI) is kept to a minimum.

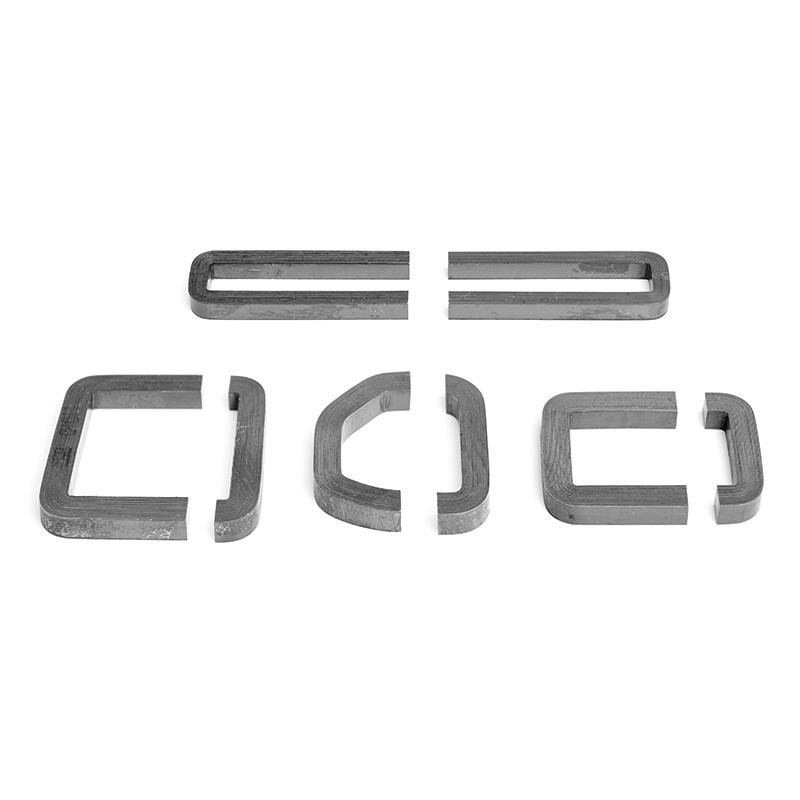

The EI transformer core is shaped as the letters E and I. The coil is wound around the leg of the core allowing for the magnetic flux to escape. As it is difficult to assemble the coil perfectly, air gaps are created, leading to transformer reluctance in these types of transformer cores.

The transformer core doesn't have sharp corners, ensuring the magnetic field doesn't interfere with the surrounding circuits and remains within the transformer core.

The Toroidal transformer core has a wide variety of applications. These transformer cores are used in battery chargers, computers, TVs, inverters, audio systems, and medical industry equipment.

The toroidal transformers are appropriate for equipment used in the medical industry as these transformers offer superior efficiency, low leakage, and noiseless performance.

These compact and lightweight transformer cores make them well-suited for medical systems with space constraints.

The toroidal transformer keeps the sound degradation, noise level, and distortion to a minimum, making them ideal for audio amplifiers. The coils wound tightly around the core, and the magnetic field staying within the donut shape ensures that the sound delivered is clean and accurate.

Toroidal transformer cores weigh half the weight of conventional transformers, making them well-suited for power inverters and compact electrical devices. The windings are evenly dispersed to ensure maximum utilization of the space. Also, most toroidal transformers come with a thermal switch to prevent the core from overheating.

The toroidal transformer core has several benefits, such as low stray losses, minimum audible hum, and better electrical efficiency, making it an excellent choice for use in household equipment.

Core losses occur when the magnetic flux tries to leave the steel grain. However, the toroid transformer core has no air gaps because of its compact size and curved edges. The absence of air gaps means low transformer reluctance and hence low stray losses.

The tightly wound coils and absence of air gaps help to decrease hum and dampen the acoustic noise. The core is coated with epoxy resin to ensure there are no loose layers that can cause vibration. Even if the hum is heard in the beginning, the superior quality of electric steel ensures that the hum is completely eliminated.

The cores are 90% efficient compared to traditional transformers as it delivers a higher output with less input. This is achieved because of the even winding distribution and supreme quality particle steel.

The toroidal transformer core is shaped as a donut to ensure the primary and secondary coils are evenly assembled over the transformer core. As the coils are tightly wound, magnetic flux losses are minimal, resulting in higher electrical efficiency compared to EI transformer cores. Transformer core manufacturers suggest determining the kind of wire, the number of winding turns, the cross-section of the wire, and the wire gauge before making a soft magnetic cores.

Copyright © 2025 TRANSMART INDUSTRIAL LIMITED | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.