Contact Transmart

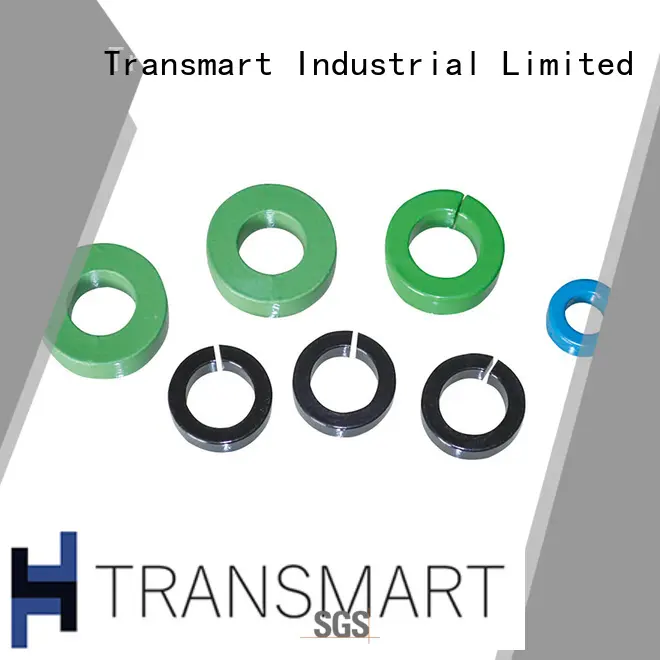

Transmart new amorphous elements supply for renewable energies

Model::

AC Series, PFC Series

MOQ:

200 PCS per item

Origin:

China Foshan

Lead time:

4-15 Working days

Payment:

L/C D/A D/P T/T Western Union

Service:

OEM,ODM,Customized

Product Details

Choose Transmart Industrial's soft magnetic materials for the following reasons.soft magnetic materials, manufactured based on high-quality materials and advanced technology, has reasonable structure, excellent performance, stable quality, and long-lasting durability. It is a reliable product which is widely recognized in the market.

1. The delivered Transmart is manufactured by utilizing superior quality raw materials in accordance with global quality standards.

2. It has a strong and tough structure. It is able to withstand pressure and heavy load without fracture or breaking problems.

3. The product is easy to set up and adjust. The inter-locking keys at one end allow it to be properly and easily fixed after unfolding.

4. Comprehensive sales network makes the amorphous elements shopping experience more convenient.

5. To be a dominant amorphous elements supplier, Transmart has been strictly carried out the quality assurance.

Company Features

1. It is the quality amorphous elements and excellent service that makes Transmart Industrial Limited the leader in the industry.

2. Advanced production technology of has been introduced in our factory.

3. In the enterprising spirit of 'Pursuit of Excellence', our company strives to develop in a rapid and steady way. By deepening communication, we will work hard to assist customers to design, develop, and manufacture the accurate products they need. Increasing customers' satisfaction is our business goal. We will go all out to improve our service ranges, including raw materials sourcing or product customizing.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Address

Room 1113, Block 7, TianAn Center,

31 East Jihua Road, Foshan 528200, China

Better Touch Better Business

Contact Sales at TRANSMART.

+86 757 8622 8688

Copyright © 2026 TRANSMART INDUSTRIAL LIMITED | Sitemap | Privacy Policy