Contact Transmart

Transmart current factory for audio system

- Transmart Industrial always keeps in mind the service principle of 'customer's needs can not be ignored'. We develop sincere exchanges and communication with customers and offer them comprehensive services in accordance with their actual demands.

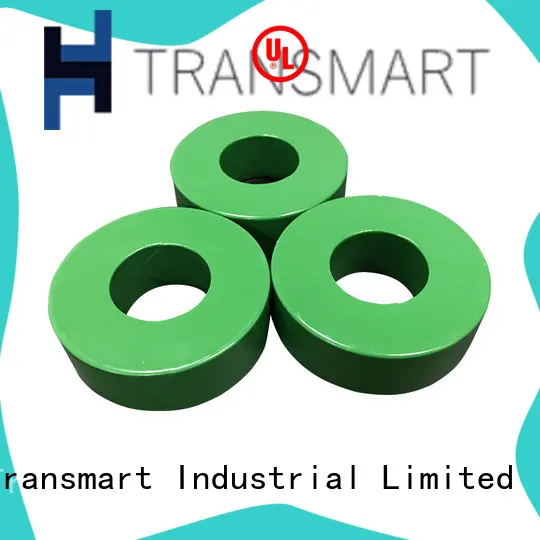

1. Transmart is produced in a safe and clean environment.

2. The product meets the most stringent quality requirements and can be used for quite a long time.

3. It is created according to strict performance standards. It is tested against other comparable products on the market and goes through real-world stimulation before going to the market.

4. This product ensures the good visual weight of the space. Its height, volume, and shape will give people a vision and experience around the space.

5. This garment helps an individual to reflects taste. One can make a statement and express himself or herself to hook on people’s attention.

Company Features

1. As a domestically and internationally competitive enterprise, Transmart Industrial Limited primarily focuses on .

2. We have teams of professional R&D and well-trained customer service staff. They are able to provide custom-made products or professional advice to our customers.

3. Transmart Industrial Limited is committed to in filed. Ask! Transmart Industrial Limited always keeps in mind that quality is everything. Ask! Implementing the tenet of silicon steel density with our heart and soul, we sincerely serve the enterprise. Ask! Transmart wishes to take the lead in becoming the leading m36 silicon steel manufacturer. Ask!

With the rapid development of the world automobile industry and transportation industry, the demand of various tires is increasing day by day. At present billions of tire and plastic is sold annually all over the world.According to statistics, 50%-55% raw rubber are used for tire manufacture every year. For security, automobile should change tires every 30,000 -50,000km.In this way, billions of waste tire, 17 million tons will be produced in one year.Waste tire is a kind of non-fusible or refractory polymer elastomer material, it needs hundreds of years for the large molecules decompose to be no affect to normal growth of plant in the earth.

With the rising of public awareness for environment protection, Waste tire recycling and renewable has been attracted more and more attention all over the world.

4 sets of 10 ton pyrolysis machine of tyre installed in Indonesia

1. Reactor made of Q245R boiler steel plate, 16mm/18mm thickness.

2. Integrated design condensing system and dedusting device shorten the installation time and the welding quality can be ensured. besides , it is easy for transportation.

3. Pyrolysis oil can be used for heating the reactor , one set machine need 3-4 oil burners.

4 we have different grades dedusting devices to meet different countries emission standard.

5. A serious of safety devices to ensure the machine working smoothly.

6. Tail gas (can not be turned into liquid oil but combustible oil gas ) are go back to the furnace for second burning as heating fuel to heat the reactor , thus to prevent pollution.

1. Tyre /Plastic Pyrolysis machine installed in Greece.

2. Make underground foundation for the pyrolysis reactor , we will send engineer to guide installation and training workers operate the machine.

3. One year warranty.